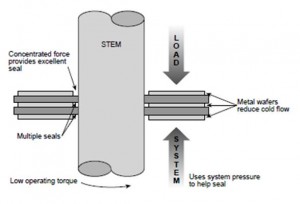

Dyna-Pak® provides superior sealing performance while reducing maintenance costs. Consisting of alternate wafers of TFE and metal spacers, stem leakage is virtually eliminated while the problems associated with TFE cold flow are minimized.

As the packing nut is tightened, metal spacers squeeze the TFE wafers, driving the TFE against the stem. At the stem, forces are concentrated and the TFE wafers provide multiple line seals. In addition to squeezing the TFE wafers, the metal spacers help contain the TFE and drastically reduce its ability to creep.

Dyna-Pak® packing has the ability to:

- Utilize system pressure to increase effectiveness in eliminating leakage.

- Provide reduced operating torque

- Help eliminate fugitive emissions

- Reduce the need for frequent packing adjustments

- Operate in temperatures from -65° to +450° F (-54° to +232° C)

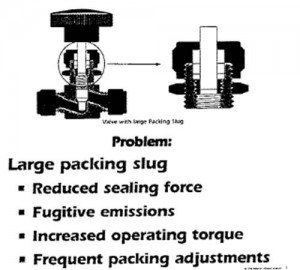

Common problems with the stem packing in other valve designs are:

- A reduced sealing force which leads to a higher chance of fugitive emissions.

- Tightening packing nut to increase sealing force can apply too much load.

- Increased operating torque makes valve more difficult to operate.

In the valve image below, a large packing slug forms the seal around the stem. The sealing area is large and the sealing force is spread out, so there’s less sealing force at a given point.

When the large packing slug relaxes or cold flows, it is prone to leakage. When this occurs, it requires more frequent packing adjustments.

What features make Hoke needle valves better?

The Dyna-Pak® consists of alternating wafers of Teflon seals and metal disks. As a result:

- Cold flow is limited because of smaller size and support of Teflon wafers. Cycle life is increased and packing nut adjustments are required less frequently.

- Provides multiple sealing points with a more concentrated sealing force than packing slug. A better sealing force means reduced fugitive emissions. Additionally, since the packing nut doesn’t require as much tightening the valve is easier to operate.

- Uses system pressure to provide a better seal under high pressure. Provides a wide range of capabilities with a long cycle life.

.jpg)